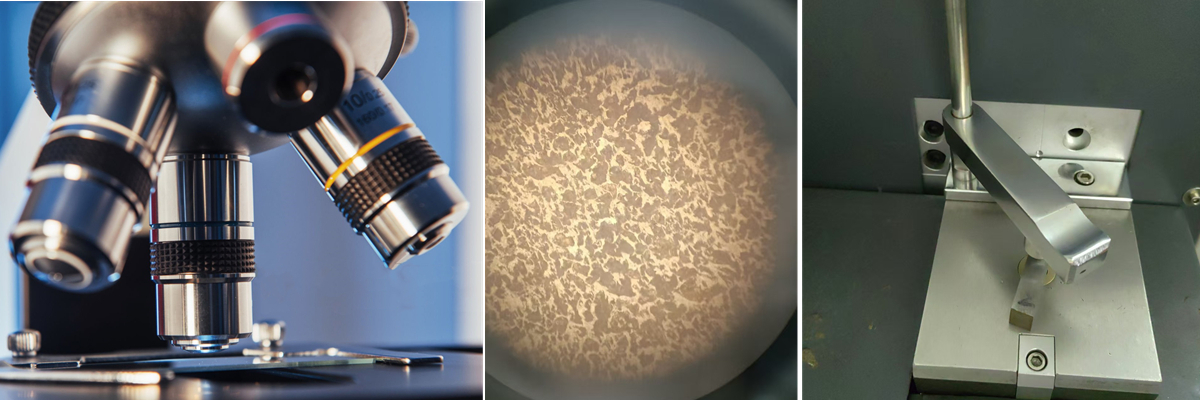

Microstructure Analysis

LIHUA has its own metallurgical laboratory where the microstructure of the steel alloy can be analysed in detail. Metallurgical specialists at LIHUA will be glad to help you with the interpretation of the analysis and recording the specifications that the alloy must satisfy.

If the casting is given an additional heat treatment and surface coating, this can also be analysed in detail. The measurement results are part of the sampling, so that the definitive version of the casting is recorded precisely.

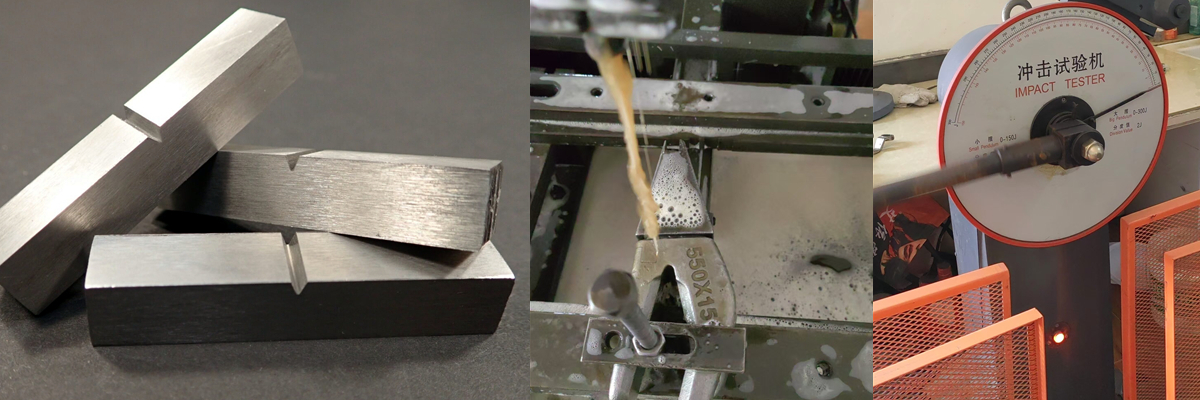

Charpy Pendulum Impact

During the production of castings, various technical and quality problems can arise. LIHUA reduces these problems as much as possible in the development phase. We design and produce castings that are suited optimally to the application, in close cooperation with our customers. Our technical and professional specialists have the knowledge and experience to advise and support you well.

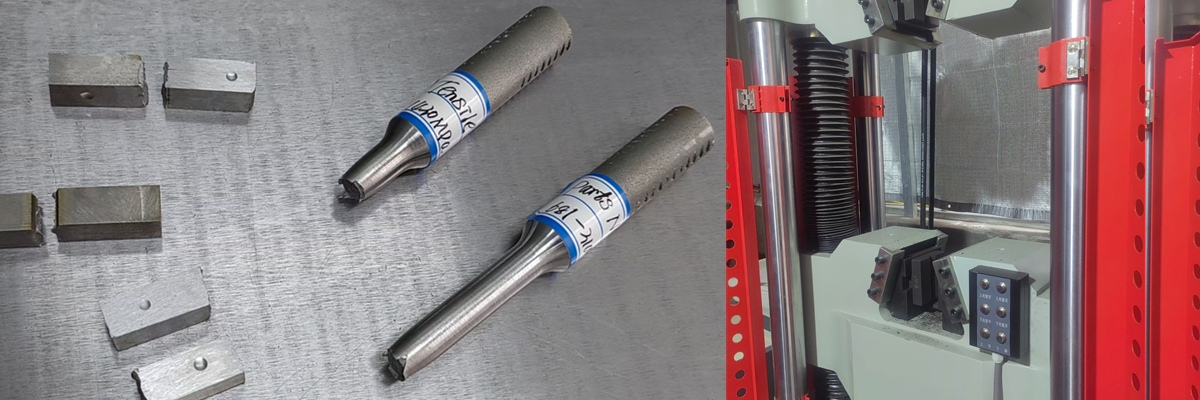

Special Inspection Tool

For parts that require complex internal geometries, we utilize a range of special inspection tool options,to ensure that the features of your parts match your requirements.

Measurement Report

At LIHUA, once the first pieces have been cast part, the product is inspected for its dimensions. In this manner, customers and LIHUA technicians have a good picture of the dimensioning of the cast piece. All of the measurement data are summarised in a measurement report so that the definitive version of the cast piece is recorded precisely.