Air suspension kits series trailing arms

Colour: Original / Black

Materials: Spring Steel /52CrMnMoV

Production Processes:

Hot Rolling / Forging Process

Heat Treatment:

Normalizing, Annealing, Quenching, Tempering

Surface Finish:

Shot Blasting, Polishing, Baking Varnish

Certificates: IATF16949

Transport Package: Wooden Case

Delivery Time: 15-20 Days

Leaf springs are suspension systems that consist of multiple thin, curved metal strips, or "leaves," stacked on top of each other and held together by clamps or bolts at their centers.

We offer the complete product range for spring, truck suspension, steering, driveline, coupling, and hitch product lines. These parts are unmatched in their material, quality and operation. You can find everything you need under one roof. With unwavering precision during manufacturing, our leaf springs meet the highest quality standards and are engineered to withstand even the harshest road conditions. Rigorous quality control checks guarantee their reliability and longevity.

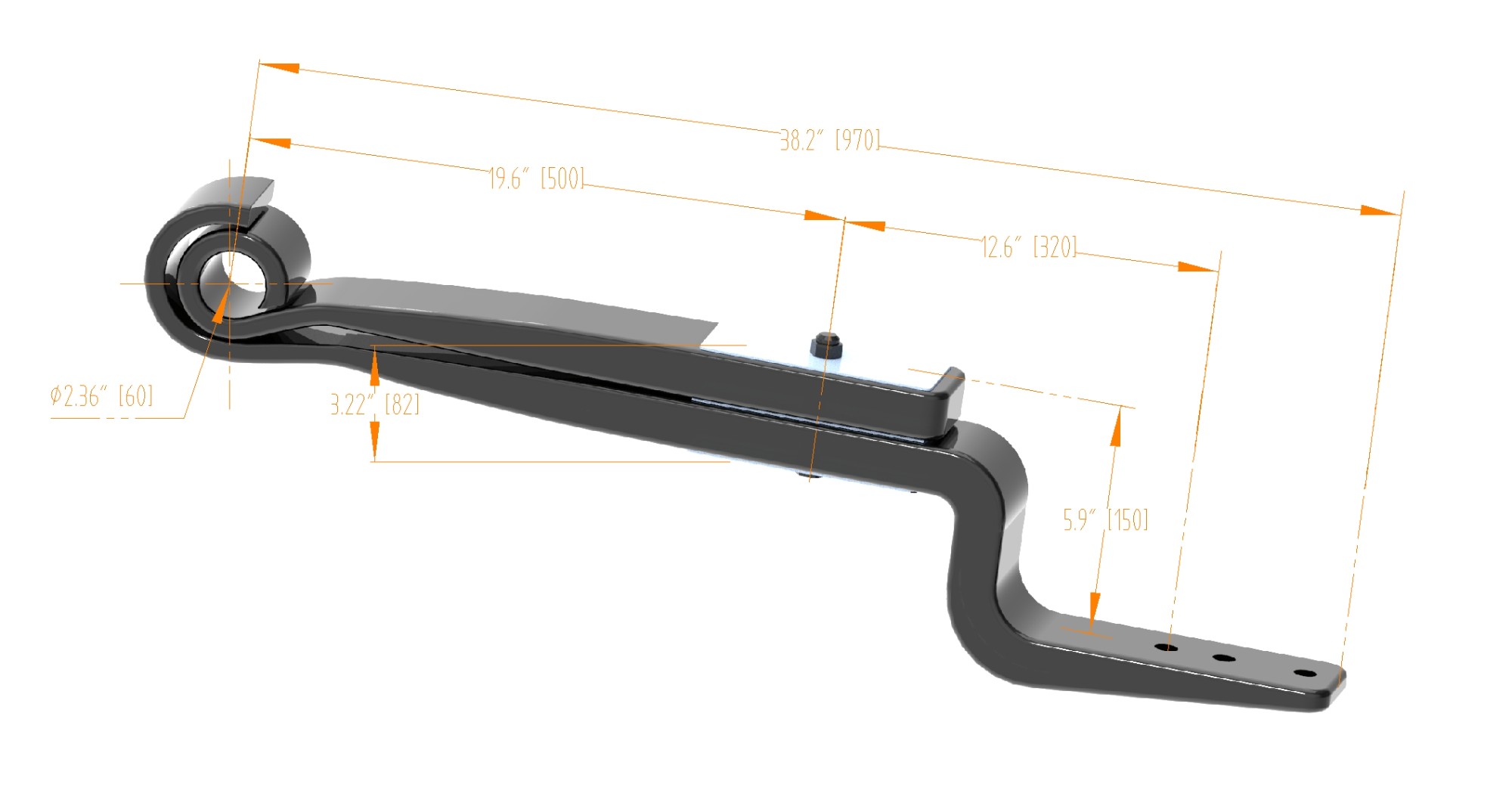

| Specifications | |||

| Working length (L) | 38.2" [970 mm] | Total thickness(H) | 3.22" [82 mm] |

| Front end length (L1) | 19.6" [500 mm] | Free camber height(H1) | 5.9" [150 mm] |

| Rear end length (L2) | 12.6" [320 mm] | Spring Eye diameter (D) | 2.36" [60 mm] |

| Total weight | 1211b /55 KG | Bush in diameter (D1) | 0.96" [24.5 mm] |

| Number of leaves | 2 | Width (W) | 3.93" [100 mm] |

| Technologies | |||

| Tensile Strength(MPa) | ≥1400 | Materials | 51CrV4/52CrMoV4/60CrMo3-3 |

| Yield Strength(MPa) | ≥1200 | Production Processes | Hot Rolling/ Forging Process |

| Impact (J) | ≥45 | Certificates | IATF 16949 |

Hardness (HB) | 380-430 | Heat Treatment | Normalizing, Quenching, Tempering |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Susan

Phone: +86185 0588 9333

E-mail: lihuacastings@vip.163.com

Whatsapp:+86185 0588 9333

Add: 1588 Jiangnan Road Ningbo High-tech Industry zone