Spring end Cap-overslung Axle For Suspension Parts

Colour: Original / Black

Materials: High quality alloy steel

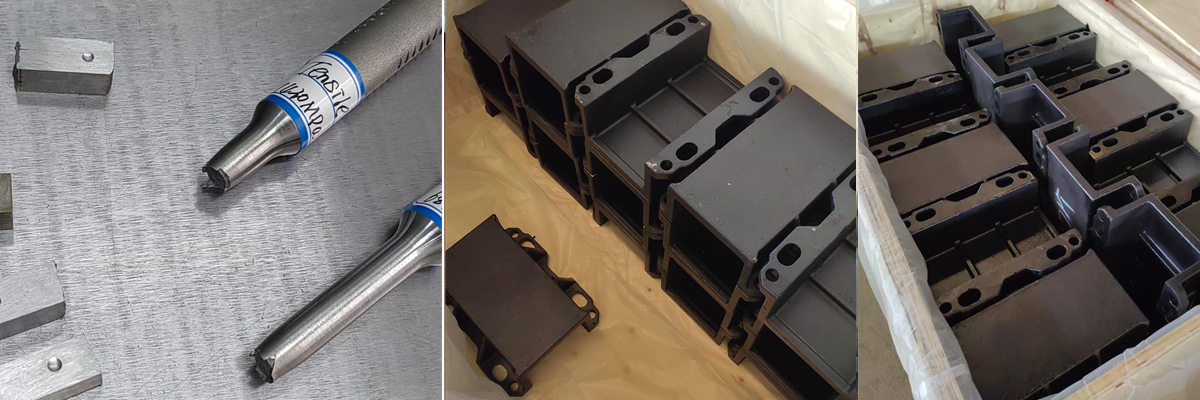

Production processes: Casting process

Precision CNC machining

Heat Treatment:

Normalizing, Annealing, Quenching, Tempering

Surface Finish:

Shot Blasting, Polishing, Baking Varnish

Certificates: IATF16949

Transport Package: Wooden Case

Delivery Time: 15-20 Days

LIHUA offer the complete product range for spring, truck suspension, steering, driveline, coupling, and hitch product lines. These parts are unmatched in their material, quality and operation. You can find everything you need under one roof. With unwavering precision during manufacturing, our trunnion hub-upper half meet the highest quality standards and are engineered to withstand even the harshest road conditions. Rigorous quality control checks guarantee their reliability and longevity.

| Specifications | |||

| Part No | 160-00092 | Total thickness (H) | 3-7/8" [98.4 mm] |

| Total Length | 11" [280 mm] | Width (W) | 5" [127 mm] |

| Pitch-row (h) | 9-5/16" [236.5 mm] | Shaft mounting | 9-5/16" [236.5 mm] |

| Pitch-row (v) | 7-1/4" [184.5 mm] | Bolt hole | 3/4" [19 mm] |

| Total weight | 17.6 lb /8 kg | U - Bolt | 3/4" -16 Thread |

| Technologies | |||

| Tensile Strength(MPa) | ≥1200 | Materials | Alloy steel |

| Yield Strength(MPa) | ≥980 | Production Processes | Casting Process |

| Impact (J) | ≥50 | Certificates | IATF 16949 |

Hardness (HB) | 180-230 | Heat Treatment | Normalizing,Quenching |

Cast Trunnion Hub-upper

Half extra heavy-duty 5 inch wide leaf springs. Accurate spring alignment preserved by the use of rugged spring guides on the trunnion casting. A split trunnion casting permits easy maintenance and replacement of trunnion bushings. Axle alignment and realignment made possible by adjustable plates within the spring-end boxes. One adjustment plate on each axle is welded at the factory. After axle alignment is completed, the installer welds the other adjustment plate to ensure sustained axle alignment. For increased life and flexibility, thick rubber pads are used above the spring leaves in the axle boxes. This construction permits greater twist freedom in the spring box a standard flexibility feature that reduces wear and promotes better ride characteristics.

These products are inspected internally at LIHUA for their dimensioning and material properties, among other things. If so desired, destructive, non-destructive or microstructural analysis can also be performed. In addition the components are delivered to the customer for evaluation. The customer can test the product for functionality, dimensions, strength, appearance and various other important parameters. Based on the results, it is determined whether the product is ready to be produced in series or if additional technical adaptations need to be implemented. High product quality is safeguarded by means of this intensive evaluation phase, as is a stable production process and a high degree of delivery reliability.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Susan

Phone: +86185 0588 9333

E-mail: lihuacastings@vip.163.com

Whatsapp:+86185 0588 9333

Add: 1588 Jiangnan Road Ningbo High-tech Industry zone