1U3352 Bucket teeth and Adapter 3G8354

Colour: Original / Black/ Yellow

Materials: Chromium Molybdenum Alloy

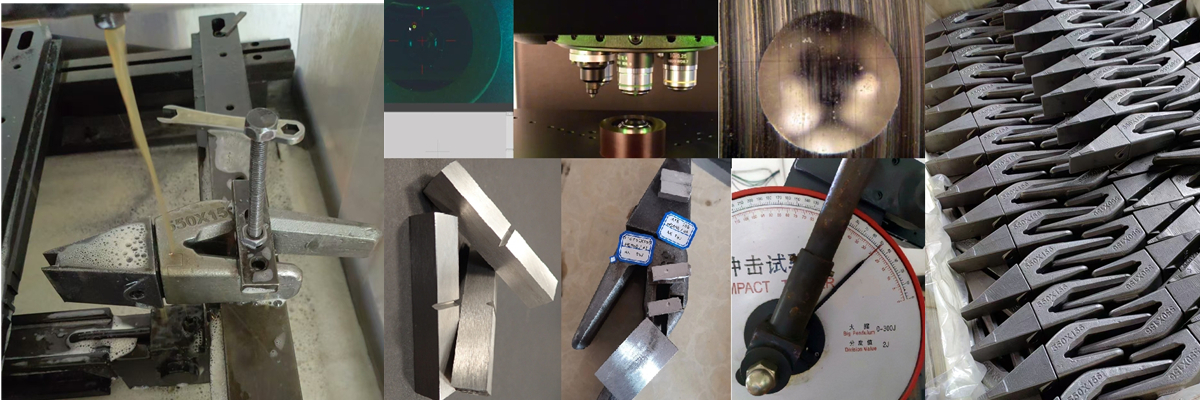

Production processes:

Lost-Wax /Precoated Silica Sand

Heat Treatment:

Normalizing, Annealing, Quenching, Tempering

Surface Finish:

Shot Blasting, Polishing, Baking Varnish

Certificates: ISO9001-2005

Transport Package: Wooden Case

Delivery Time: 10-15 Days

LIHUA castings is a provider of casting parts solutions. From casting Wear Parts to excavator buckets, bucket teeth, and cutting edge blades, we specialize in delivering innovative and high-quality products tailored to meet the diverse needs of our clients.

At LIHUA, our commitment to excellence extends to our manufacturing processes. To this end, a great deal of attention has been paid to all aspects, starting from the design to the selection of raw materials and production processes.

| Specifications | |||

| Part No | 1U3352 + 3G8354 | Total thickness(H) | 4.25" [108 mm] |

| Bucket Tooth | 1U3352 | Total Length(L) | 20.86" [530 mm] |

| Adapter | 3G8354 | Width | 3.93" [100 mm] |

| Pin/washer | 8E-6358/8E-6359 | Type | Pin/washer |

| Weigth | 15.7kg / 34.54lb | Colour | Original / Black/ Yellow |

| Technologies | |||

| Tensile Strength(MPa) | ≥1350 | Materials | Chromium Moly Alloy |

| Yield Strength(MPa) | ≥1100 | Production Processes | Lost-Wax/ Silica Sand |

| Impact (J) | ≥25 | Certificates | IS09001-2005 |

Hardness (HB) | 450-520 | Heat Treatment | Normalizing, Quenching, Tempering |

| LIHUA Bucket Teeth and Adapter List | |||||

| J Series | Teeth (Part No) | kg/lb | Pin & Washer | Adapter(Part No) | kg/lb |

J 200 | 1U3202 | 1.4/3.08 | 8E-6208/8E-6209 | 119-3204 weld on 1" | 1.1/2.42 |

| 1U3202WTL | 1.3/2.9 | same | same | same | |

| 1U3202TL | 1.32/2.95 | same | same | same | |

| 1U3202F | 1.25/2.75 | same | same | same | |

J 225 | 6Y3222 | 2.27/5.0 | 6Y-3228/8E-6259 | 623224 weld on 1" | 2.72/6.0 |

J 250 | 1U3252 | 3.09/6.8 | 8E-6258/8E-6259 | center 1U0257 bolt on | 9/19.8 |

| 1U3252SYL | 3.18/7.0 | same | 6Y3254 weld on 1" | 4.32/9.5 | |

| 1U3252TL | 3.32/7.3 | same | corner 3G4258 bolt on | 10.1/22.4 | |

| 1U3252WTL | 3.59/7.9 | same | corner 3G4259 bolt on | 10.1/22.4 | |

| 3G8250 | 3.63/8.0 | same | same | same | |

| 9N4252 | 3.9/8.6 | same | same | same | |

J 300 | 1U3302 | 4.45/9.8 | 9J-2308/8E-6259 | 3G6304 weld on 1.25" | 6.72/14.8 |

| 1U3302RC | 4.5/10 | same | center 1U0307 bolt on | 11.9/26.2 | |

| 1U3302SYL | 5/11 | same | corner 3G4308 bolt on | 16.09/35.4 | |

| 1U3302TL | 4.49/9.9 | same | corner 3G4309 bolt on | 16.09/35.4 | |

| 1U3302WTL | 5.18/11.4 | same | same | same | |

| 9N4302 | 5.59/12.3 | same | same | same | |

| 4T1300 | 5.54/12.1 | same | same | same | |

Cast teeth and adapter are used on loaders, scrapers, rippers, and scarifiers. They are formed from a medium-carbon, chromium, nickel. molybdenum steel offering high strength and toughness with deep-hardening properties. They have excellent resistance to wear and abrasion. The manufacturing process begins with the pattern which is basically an exact duplicate of the tooth to be cast but slightly over sized to compensate for steel contraction. The mold is made from this pattern.

To get the desired steel alloy, melt and heat to casting temperature in a large furnace. After this, the steel is poured in using counter-gravity. After being cast, trees must be cooled on a cooling belt (with nitrogen). The ceramic shells are broken with an utterly automatic knock-off hammer to release the trees from their containers and mostly eliminate the ceramic.

These products are inspected internally at LIHUA for their dimensioning and material properties, among other things. If so desired, destructive, non-destructive or microstructural analysis can also be performed. In addition the components are delivered to the customer for evaluation. The customer can test the product for functionality, dimensions, strength, appearance and various other important parameters. Based on the results, it is determined whether the product is ready to be produced in series or if additional technical adaptations need to be implemented. High product quality is safeguarded by means of this intensive evaluation phase, as is a stable production process and a high degree of delivery reliability.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Susan

Phone: +86185 0588 9333

E-mail: lihuacastings@vip.163.com

Whatsapp:+86185 0588 9333

Add: 1588 Jiangnan Road Ningbo High-tech Industry zone