Truck Steering Knuckle

Colour: Original / Black

Materials: High quality alloy steel

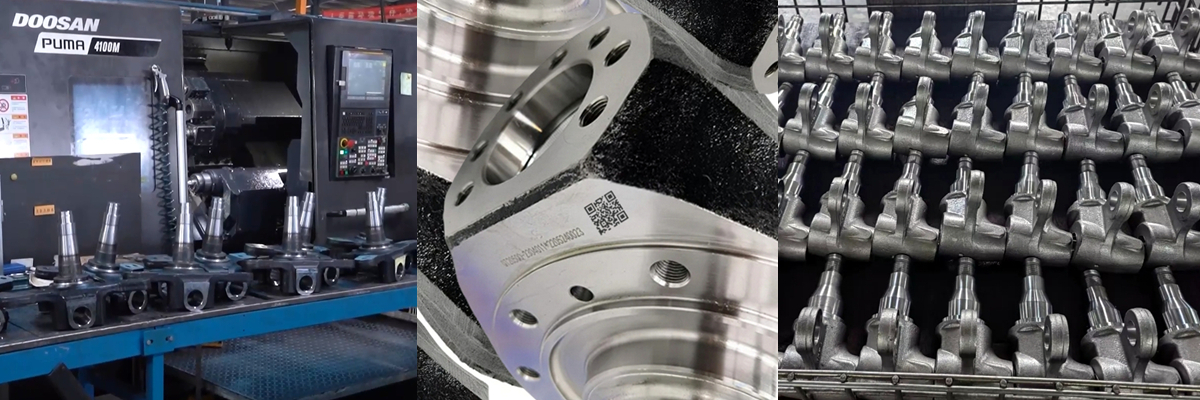

Production processes:

Precision casting process

Precision CNC machining

Heat Treatment:

Normalizing, Annealing, Quenching, Tempering

Surface Finish:

Shot Blasting, Polishing, Baking Varnish

Certificates: IATF16949

Transport Package: Wooden Case

Delivery Time: 15-20 Days

Truck Steering Knuckle

Bridge steering knuckle is one of the main parts, trailer and truck make the truck stable travel pass sensitive direction of travel, the steering knuckle’s function is to bear the load by front of truck, front wheel bearing and drive around the turn leaving the kingpin steering. In the truck while driving, changing it to bear impact load, therefore, required to have high strength.

LIHUA offer the complete product range for spring, truck suspension, steering, driveline, coupling, and hitch product lines. These parts are unmatched in their material, quality and operation. You can find everything you need under one roof. With unwavering precision during manufacturing, our trailer spring parts meet the highest quality standards and are engineered to withstand even the harshest road conditions. Rigorous quality control checks guarantee their reliability and longevity.

| Specifications | |||

Spline Number | 46 | Stop Bolt Hole | 2.75" [70mm] |

Spindle Large Diameter | 4.17" [106mm] | King Pin Bore Diameter | 2.36"[60mm] |

Spindle Small Diameter | 3.46"[88mm] | Trunnion Hanger | 3/8" [9.5 mm] |

Thread Type Wheel End | 88*1.5 mm | Spring End Cap | 5" [127mm] |

Total Weight | 55lb / 25kg | ||

| Caliper Mounting Hole Diamete | 3/4"[19mm] | Caliper Mounting Hole Quantity | 8 pcs |

| Technologies | |||

| Tensile Strength(MPa) | ≥1400 | Materials | Alloy steel |

| Yield Strength(MPa) | ≥1100 | Production Processes | Lost-wax / silica sand |

| Impact (J) | ≥50 | Certificates | IATF 16949 |

Hardness (HB) | 280-325 | Heat Treatment | Normalizing,Quenching |

We were using the “lost-wax” and precoated silica sand method that produces complex castings with extreme precision .LIHUA is your development partner for successful castings, with the objective of achieving an optimum cast in joint consultation. By means of the lost wax and precoated silica sand method, high quality investment castings are produced with complex shapes and high dimensional accuracy. Besides that, this process offers a great degree of freedom in design and material choice. Your specific wishes and demands can be incorporated into the castings. By our decades long experience with the lost wax method, we can assure you a very efficient production process and top quality castings.

These products are inspected internally at LIHUA for their dimensioning and material properties, among other things. If so desired, destructive, non-destructive or microstructural analysis can also be performed. In addition the components are delivered to the customer for evaluation. The customer can test the product for functionality, dimensions, strength, appearance and various other important parameters. Based on the results, it is determined whether the product is ready to be produced in series or if additional technical adaptations need to be implemented. High product quality is safeguarded by means of this intensive evaluation phase, as is a stable production process and a high degree of delivery reliability.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Susan

Phone: +86185 0588 9333

E-mail: lihuacastings@vip.163.com

Whatsapp:+86185 0588 9333

Add: 1588 Jiangnan Road Ningbo High-tech Industry zone